Guangdong Kuaima Sanwei Technology Co., Ltd.

Kuaima Sanwei is a rapid prototype and manufacturing expert with

over 7 years experience.

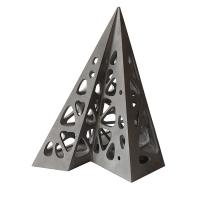

We provides professional high-end industrial quality 3D printing,

rapid prototyping and short run production manufacturing service.

Our expertise in additive manufacturing, high-end functional

testing prototypes, 24 hours services, competitive price, on time

delivery drop- shipping to over 150 countries to help you transform

your ideas into projects, bring your innovative products to market

faster, reduce your production costs, save your research and

development time.

Kuaima Sanwei is your best partner of rapid prototype and

manufacturing.